Production process and optimization methods of automatic welding robotic arm

Release time:

Feb 12,2025

Automatic welding manipulator is one of the indispensable and important equipment in modern industrial production.

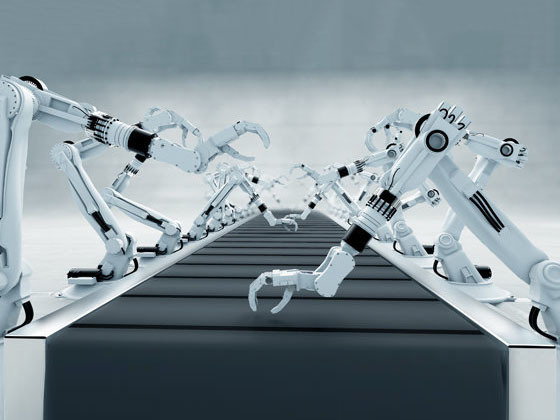

Automatic welding manipulator is one of the indispensable and important equipment in modern industrial production. Its emergence has made welding work more efficient and accurate, greatly improving production efficiency and quality. This article will provide a detailed introduction to the production process and optimization methods of automatic welding robotic arms, helping readers better understand and apply this technology.

Let's learn about the production process of automatic welding robots together. The production of automatic welding robotic arms includes three main stages: design, manufacturing, and debugging. In the design phase, engineers draw the structure and appearance drawings of the robotic arm based on the customer's needs and welding process requirements. Then, during the manufacturing phase, each component is processed, assembled, and debugged according to the drawings to form a complete automatic welding robotic arm. During the debugging phase, engineers will conduct various functional and performance tests on the robotic arm, and make necessary adjustments and optimizations to ensure that the robotic arm can operate normally.

To optimize the production process of automatic welding robotic arms, we can adopt the following methods. Firstly, plan the production process reasonably, minimize the transmission time of materials and information, and improve production efficiency. Secondly, optimize the structural design of the robotic arm to make it more stable and flexible, and improve motion accuracy and speed. In addition, automated production equipment and processes can be introduced to reduce the number and time of manual operations and lower production costs.

In addition to the optimization methods mentioned above, we can also focus on materials and technology. Choosing high-quality welding materials can improve the strength and stability of welded joints. Meanwhile, adopting advanced welding technologies such as laser welding and gas shielded welding can improve welding quality and efficiency. In addition, timely maintenance and upkeep of equipment to ensure the normal operation of the robotic arm is also an important link in optimizing the production process.

In summary, the production process and optimization methods of automatic welding robotic arms are of great significance for improving the efficiency and quality of welding work. Through rational design and manufacturing, as well as optimized production processes and techniques, we can better apply automatic welding robot technology, bringing more convenience and benefits to industrial production.