Design and development technology of automatic welding manipulator

Release time:

Feb 12,2025

In modern manufacturing, automatic welding robots have become indispensable key equipment in welding operations.

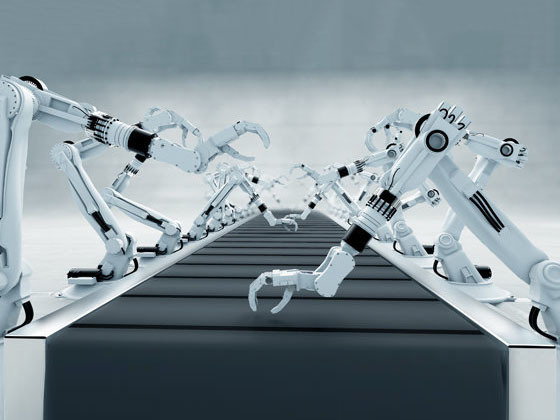

In modern manufacturing, automatic welding robots have become indispensable key equipment in welding operations. This article will reveal the design and development technology of automatic welding robotic arms, as well as their importance in production.

1、 Design principle of automatic welding manipulator

The automatic welding robotic arm achieves automation of welding operations through the collaborative work of electronic systems and mechanical structures. The design principle mainly includes three elements: control system, sensors, and mechanical structure. The control system controls the movement and speed of the robotic arm through programming, sensors are used to detect welding quality and position, and the mechanical structure determines the stability and accuracy of the robotic arm.

2、 Research and development technology of automatic welding robotic arm

In the development process of automatic welding robotic arms, multiple technical factors need to be considered. Firstly, the development of the control system requires controlling the motion trajectory and speed of the robotic arm to ensure the accuracy and stability of welding. Next is the application of sensor technology, which uses high-precision sensors to monitor parameters such as temperature, pressure, and position during the welding process, and provides real-time feedback to the control system to achieve closed-loop control. The design of mechanical structures requires consideration of factors such as the stability, load capacity, and workspace of the robotic arm to ensure that it can adapt to various welding environments and workpieces.

3、 The importance of automatic welding robotic arms in production

Automatic welding robots have many advantages in production. Firstly, it can replace manual welding, improve production efficiency and consistency, and reduce labor intensity and human error. Secondly, automatic welding robots can adapt to workpieces of different shapes and sizes, achieving flexible and diverse welding operations. In addition, the high precision and stability of the robotic arm effectively ensure the welding quality, improving the reliability and stability of the product.

In short, the design and development technology of automatic welding robotic arms are crucial for modern manufacturing. It not only improves production efficiency, but also provides high-quality welding operations. With the continuous advancement of technology, it is believed that automatic welding robots will have a wider range of applications in the future.