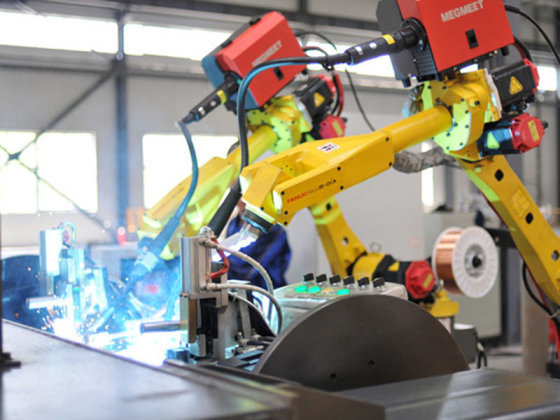

Application of welding robots in the electronics industry

Release time:

Feb 12,2025

With the continuous development, the electronics industry has also begun to introduce welding robots to keep up with the pace of the times.

With the continuous development, the electronics industry has also begun to introduce welding robots to keep up with the pace of the times. Industrial robots have improved the welding quality of products and also increased production efficiency, satisfying the increasing demand for electronic products from the public and promoting the development of the electronics industry towards intelligent welding.

With the increasing demand for intelligent electronic products among the public, the electronics industry is also facing challenges. In the electronics industry, there is a need to ensure the accuracy of welding operations and improve the stability of welding operations. Traditional welding is affected by manual factors, resulting in a lack of welding accuracy. The use of welding robots has solved the process difficulties.

The use of welding robots in the electronics industry:

1. Improve welding accuracy. Electronic components require precise welding, which has high requirements for the technical parameters and welding accuracy of welding robots. Welding robots have a compact structure and can automatically locate small welds, completing fine laser welding. The welded joints are beautiful and firm, and laser welding does not require welding data, saving welding data.

2. High flexibility in welding. Adopting a six axis lightweight welding robot, it has a small rated load capacity and occupies a small space. Small welding robots are compact in size and can complete tasks in any space. They can be used in combination with different welding units to ensure repeated welding accuracy during continuous operations and are suitable for welding different electronic workpieces.

3. Good environmental adaptability. Traditional welding operations are simple and can cause harm to workers' bodies. Long term contact can lead to industry diseases. Welding robots can complete automated welding operations, replacing manual labor in harsh environments. Welding robots are not disturbed by external environments when welding electronic workpieces, completing stable welding operations.

4. Good safety. The welding robot has a control system that integrates robot control, motion control, and welding process control. It can harmonize the functions of various parts during the welding process, complete the automation of welding, and has multiple sensors and functions. When welding problems occur, an alarm signal will be issued, and the operator can troubleshoot and inspect them based on the signal.

With the continuous development of the electronics industry, helping to stabilize welding quality in welding operations, improving welding efficiency in the electronics industry, completing precise welding of electronic components, satisfying the welding mission of different workpieces in the electronics industry, is conducive to meeting the demand for automation and intelligence in the electronics industry.