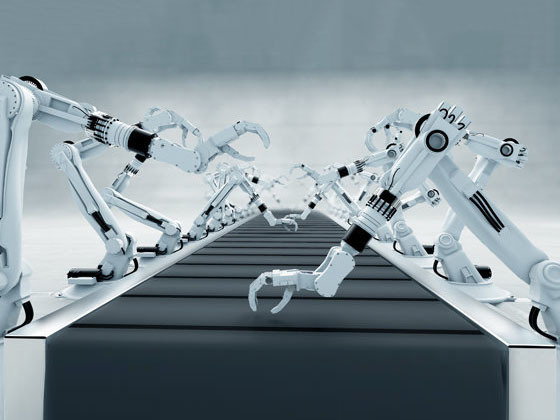

Advantages and Cost Comparison of Welding Robots

Release time:

Feb 12,2025

Welding parameters such as welding current, voltage, welding speed, and welding elongation have a decisive effect on the welding results.

(1) Stabilize and improve welding quality to ensure uniformity.

Welding parameters such as welding current, voltage, welding speed, and welding elongation have a decisive effect on the welding results. When using robots for welding, the welding parameters for each weld seam are constant, and the quality is less affected by human factors, which reduces the requirements for worker operation skills. Therefore, the welding quality is stable. However, during manual welding, the welding speed, dry elongation, etc. are all changed, making it difficult to achieve uniformity in quality.

(2) Improved the working conditions of workers.

The use of robot welding workers is only for loading and unloading workpieces, away from welding arc light, smoke, and splashes, freeing workers from high-intensity physical labor.

(3) Improve labor productivity.

Robots have no fatigue and can produce continuously for 24 hours. Using robots for welding has significantly improved power.

(4) Clear product cycle and easy control of product output.

The production rhythm of robots is fixed, so arranging production plans is very clear.

(5) It can shorten the cycle of product modification and replacement, and reduce the corresponding equipment investment.

It can achieve welding automation for small batch products. The major difference between robots and specialized machines is that they can be programmed to adapt to the production of different workpieces.

(6) To improve the automation level of factories, we can request the government to provide automation renovation costs for enterprises.