Working principle and optimization method of automatic welding manipulator

Release time:

Feb 12,2025

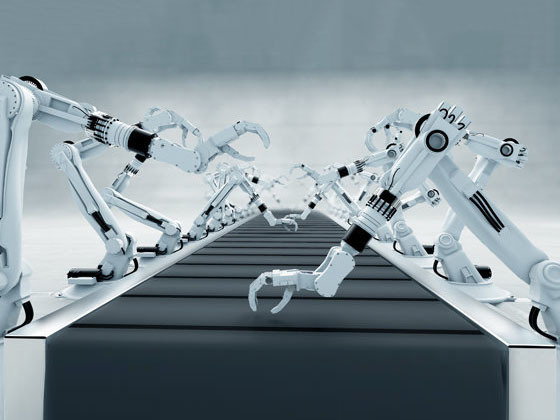

Automatic welding robotic arm is an efficient industrial robot widely used in welding automation production.

Automatic welding robotic arm is an efficient industrial robot widely used in welding automation production. It can automatically perform complex welding operations, improving production efficiency and product quality. This article will introduce the working principle and optimization methods of automatic welding robotic arms.

The working principle of an automatic welding robot mainly includes three parts: the robot body, the control system, and the welding equipment. The robotic arm body includes a robotic arm and claws, which complete various actions through servo motors. The control system includes software and hardware for programming, monitoring, and controlling the movement of the robotic arm. Welding equipment includes power supply, welding gun, etc., used to complete welding operations.

In order to optimize the production efficiency of automatic welding robots, the following points need to be noted. Firstly, carefully design the welding program, optimize the welding path, and reduce welding time and material waste. Secondly, choose appropriate welding equipment and materials to ensure welding quality and efficiency. Finally, regular maintenance and upkeep should be carried out on the robotic arm to extend its service life.

When using an automatic welding robotic arm, safety precautions should be taken. When operating a robotic arm, it is necessary to ensure the safety of personnel and avoid accidents. At the same time, attention should also be paid to the maintenance and upkeep of the robotic arm to ensure its normal operation and avoid production interruptions caused by mechanical failures.

In short, automatic welding robots are important equipment in modern manufacturing, and their methods for optimizing production efficiency and ensuring quality also need to be continuously explored and improved. We need to constantly learn and master relevant knowledge, improve our technical level, and contribute to the development of production automation.